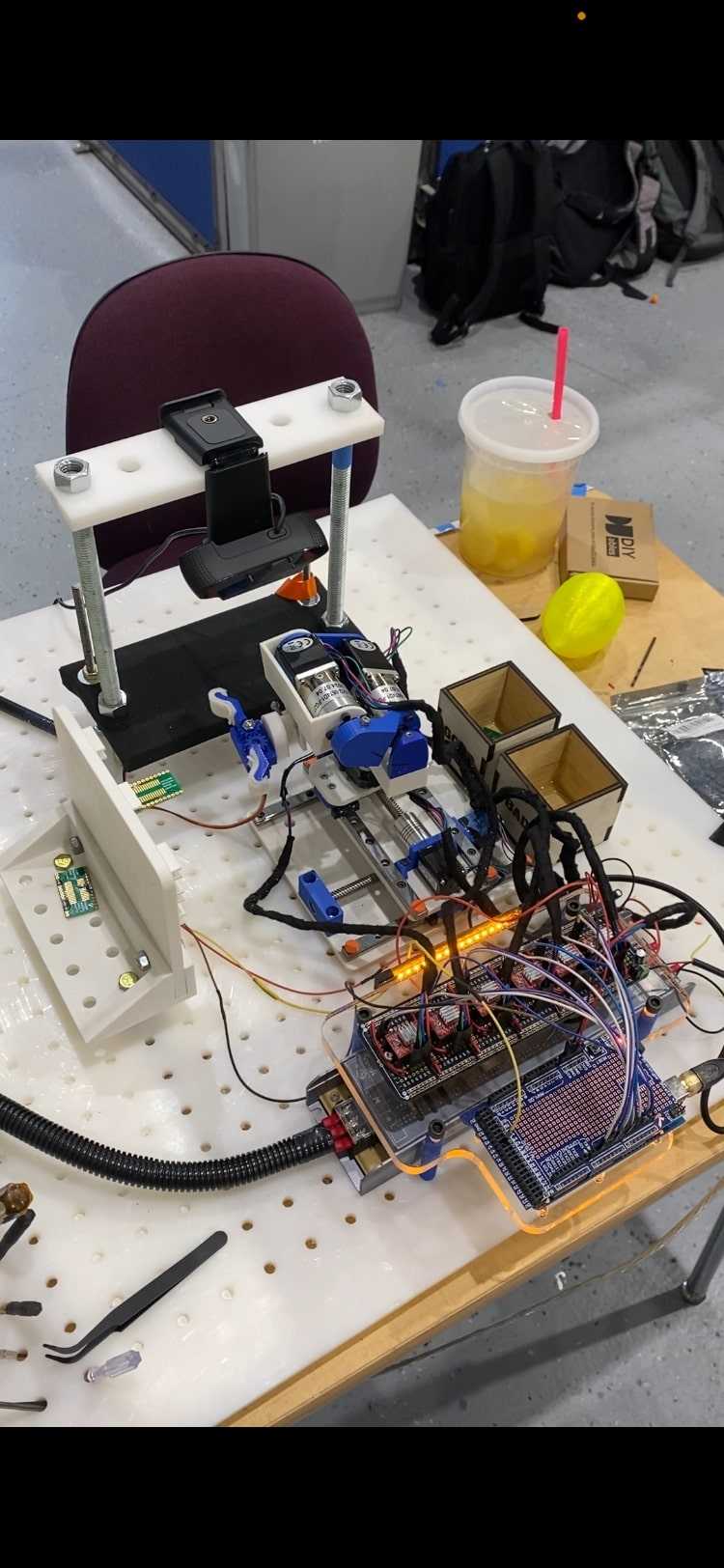

Semi Automated Parts Inspection System

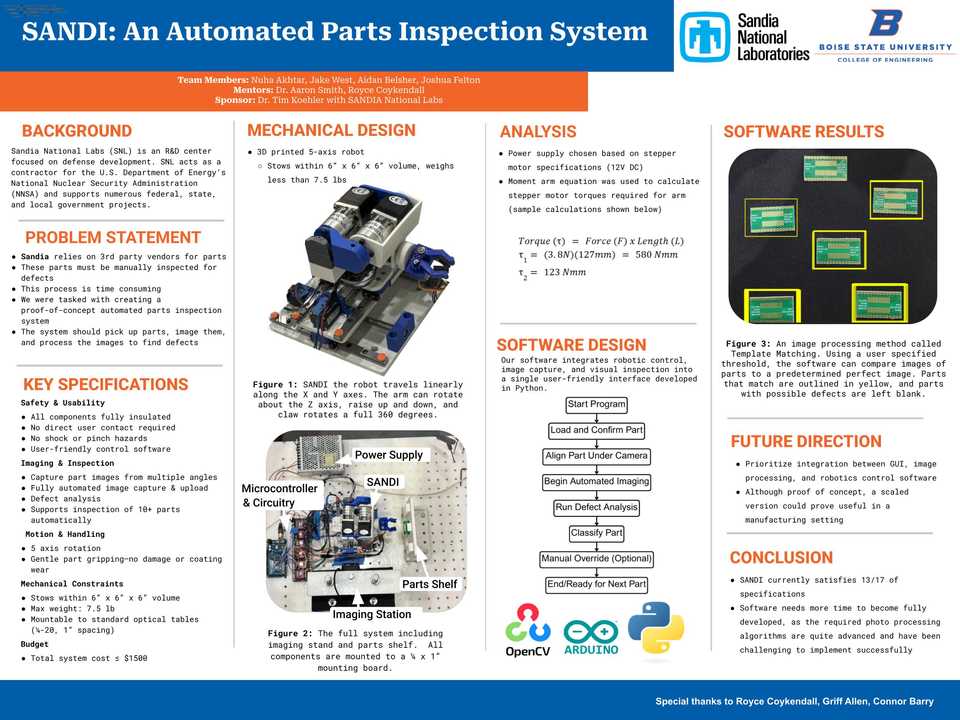

SANDIA National Labs tasked our team with creating a parts inspection system that can automatically sort good and bad parts that come from various vendors. Parts used by SANDIA have to pass strict quality standards and therefore are subject to inspection.

This inspection is currently performed by a technician. Automating this process would free up the technician to perform other tasks.

This project is part of the SANDIA National Labs Senior Design Bonanza competition.

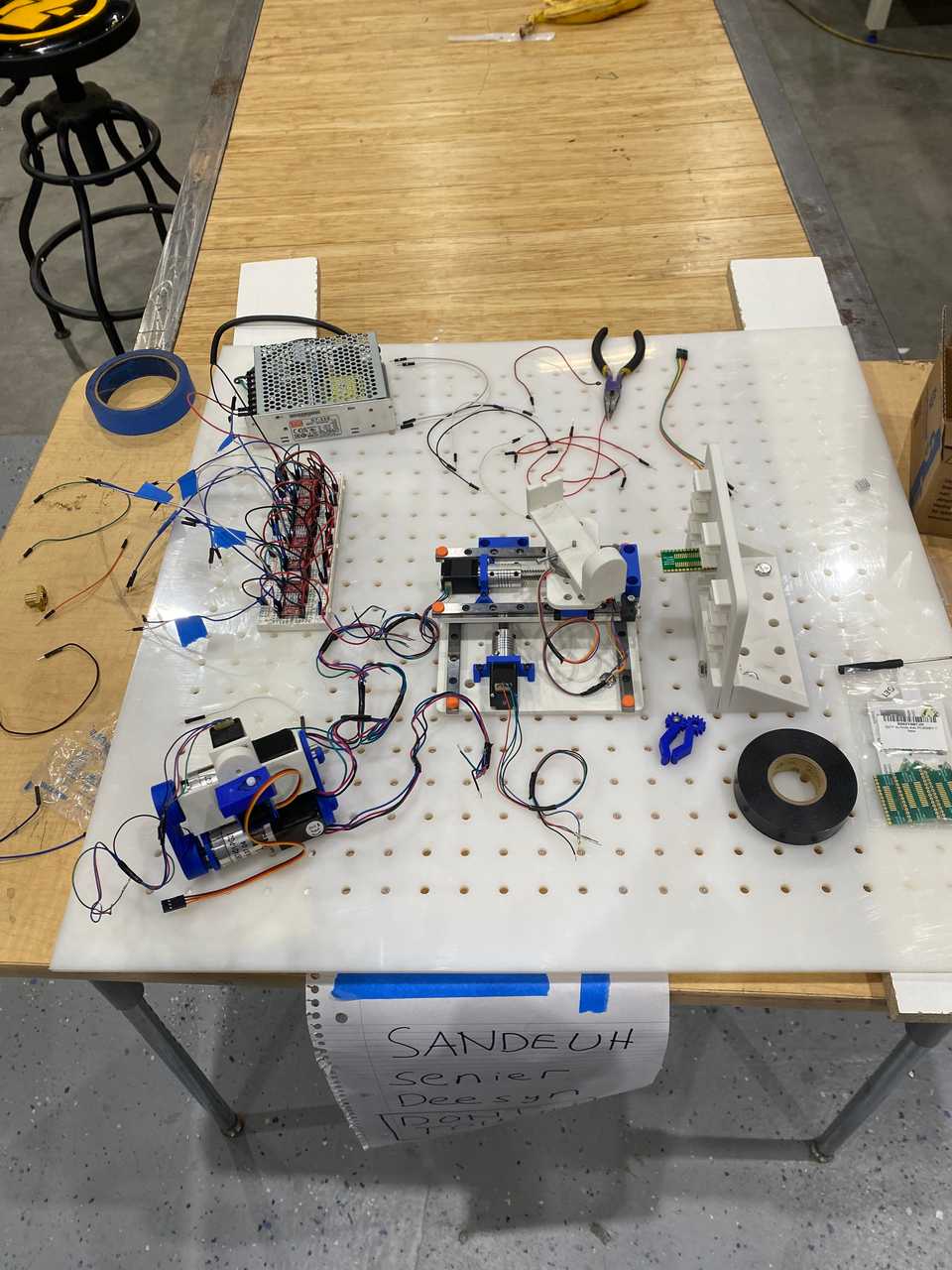

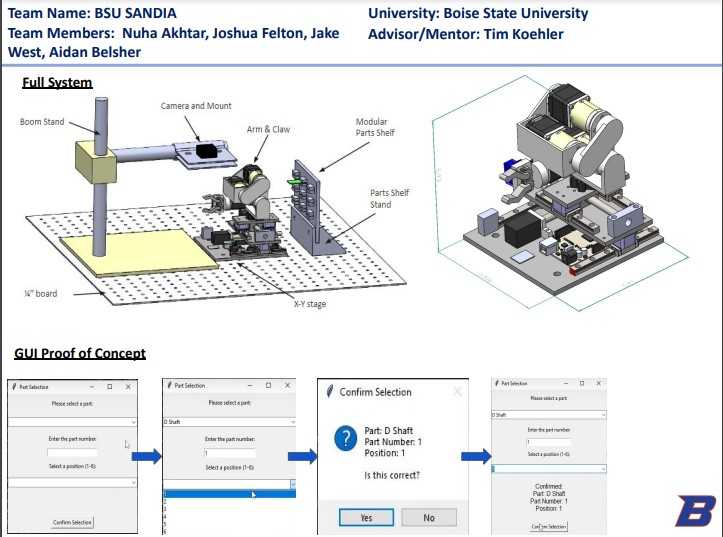

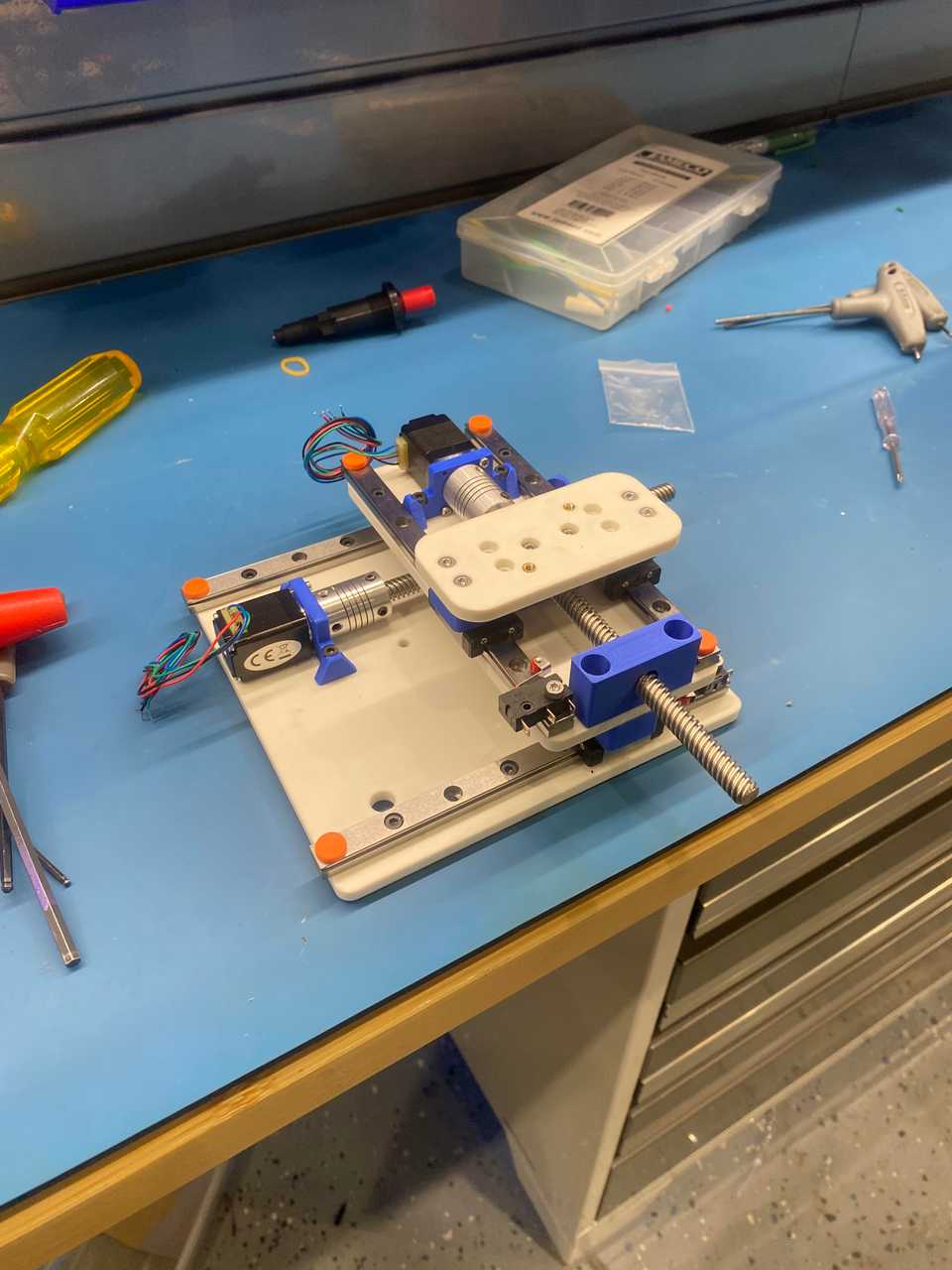

Our design features a robotic arm capable of 5 axis of movement. The arm features a claw capable of gripping multiple parts. The arm is capable of lifting 1.5 pounds thanks to gear reduced NEMA 11 stepper motors. The entire system is designed to be bolted to a 0.25x1” pegboard.

Follow this link for a video demonstration: https://www.youtube.com/watch?v=vda4ncrHNnI